Secondary Glazing Panels for Dummies

Table of ContentsThe 10-Minute Rule for Aluminum Spandrel7 Easy Facts About Aluminum Spandrel Panel DescribedSecondary Glazing Panels Things To Know Before You BuyThe smart Trick of Aluminium Spandrel Panel That Nobody is Discussing9 Easy Facts About Replacement Double Glazed Glass Panels ShownThe Only Guide for Fire Rated Spandrel Panel

Periodically, there are concerns connecting to having also much uncontrolled daytime, occasionally described as glow. The difficulty is to pursue the highest visible light passage (VT) as well as the most affordable solar warmth gain coefficient (SHGC) while not stopping the glass from being also reflective when seen from both the exterior and also the inside, while regulating glare.The devices must be totally constructed in a manufacturing facility as well as delivered to the site for installation on the building. The units are positioned on the floors, packed in cages, making use of the tower crane and also decreased right into area using a smaller sized crane or hoist had by the glazing service provider. The mullion dimensions often tend to be a little bigger than a stick system as a result of their open section as compared to television form of a typical stick curtain wall section.

Devices can be put together in a factory while the structural framework of the structure is being built. Where stick systems call for numerous steps to set up as well as seal the wall, unitized wall surfaces show up on the website entirely set up enabling the floorings to be closed in quicker (replacement double glazing panels cost). Unitized systems also call for less area on site for layout therefore providing an advantage for urban websites with room constraints.

6 Simple Techniques For Replacement Double Pane Glass Panels

The interlacing upright mullions will generally have 2 interlocking legs. One leg will be in the plane simply behind the glazing pocket and also the other at the indoor face of the mullions. The interlocking leg in the airplane of the glazing pocket will be secured by gaskets and is the key line of defense versus water and air seepage.

Equipments whose linking legs lock also jeopardize the capacity of the system to accommodate movement. Some unitized designs are sensitive to small abnormalities in the spacing of surrounding modules; for example, if the component joints are a little out of resistance, gaskets might not be correctly pressed and also wetness defense may experience.

This is where area labor should seal in between surrounding devices to achieve a climate limited wall. The interlocking legs of the straight mullions are the most essential interface of a unitized system.

What Does Curtain Wall Spandrel Panel Detail Do?

These upstanding legs have gaskets that secure against the walls of the lower horizontal. More durable systems will supply two upstanding legs with gaskets on both legs.

The stack joint is the straight joint where devices from adjoining floors fulfill. Putting the pile joint at the sill of the vision glass (commonly 30" above the flooring) will minimize the measurement of the upright mullions. This positioning makes use of the back period of the mullion above the anchoring point at the slab to counteract the deflection of the mullion below the piece (insulated metal spandrel panels).

Specify that research laboratory tests are to be conducted at an AAMA Accredited Research laboratory facility. Field Mock-up: For all drape walls, stock or personalized, call for construction and testing of a field mock-up rep of the wall/window assembly. This is ideal arranged before the launch of store illustrations for window production, to ensure that there is an opportunity to make design changes based on the test efficiency of the field mock-up.

The Best Strategy To Use For Replacement Glazing Panels

The information associated with this section of the BEDG on the WBDG were developed by board and also are meant solely as a way to show general design as well as building and construction concepts only. Proper usage and also application of the ideas highlighted in these details will certainly vary based upon efficiency factors to consider and environmental problems distinct to every task as well as, for that reason, do not stand for the last point of view or referral of the writer of each section or the committee members in charge of the advancement of the WBDG.

Constant steel sill blinking at the base of the curtain wall surface safeguards the wall surface framing listed below from leakage through the curtain wall surface. Sill spandrel panel technical guidance blinking need to have upturned end dams and fully secured corners. Intermediate straight must be wept to the exterior as well as stop water from draining pipes onto the head of the glazing unit below.

The Best Guide To Replacement Double Glazing Panels Prices

Gasket height must match to the drape wall design pressure. Pressure matched rainscreen gaskets form a primary climate seal at the face of the unitized vertical pile joint in line with the horizontal rainscreen gasket at the device sill below.

Spandrel glass adapters are used to decrease the deepness of the glazing pocket to fit reduced profile of spandrel glass. Spandrel glass adapters need to be totally bedded in sealant as well as incorporated with glazing pocket corner seals to avoid water leak from polishing pocket to structure inside. Unit measurement of mating head and also sill squeezed out accounts enables specified floor to floor deflection at the stack joint.

Intermediate horizontals stop at the face of the upright system jamb participants at each end. Units are hung from the top or face of the adjacent flooring or building framework making use of mated brackets as well as field used screws with a minimum of clearance for gain access to and assembly. All connections and brackets situated within the systems insulated or key climate seal areas are secured with ideal sealant products during field installment.

Replacement Double Glazing Panels Prices Fundamentals Explained

non-heat-treated) or completely toughened up glass to continue to be in position up until it can be replaced. Whether heat-strengthened or fully solidified, heat-treated glass products are produced in a similar fashion and making use of the exact same processing tools. The glass article source is heated to roughly 650 C (1200 F), then force-cooled to produce surface area and also side compression.

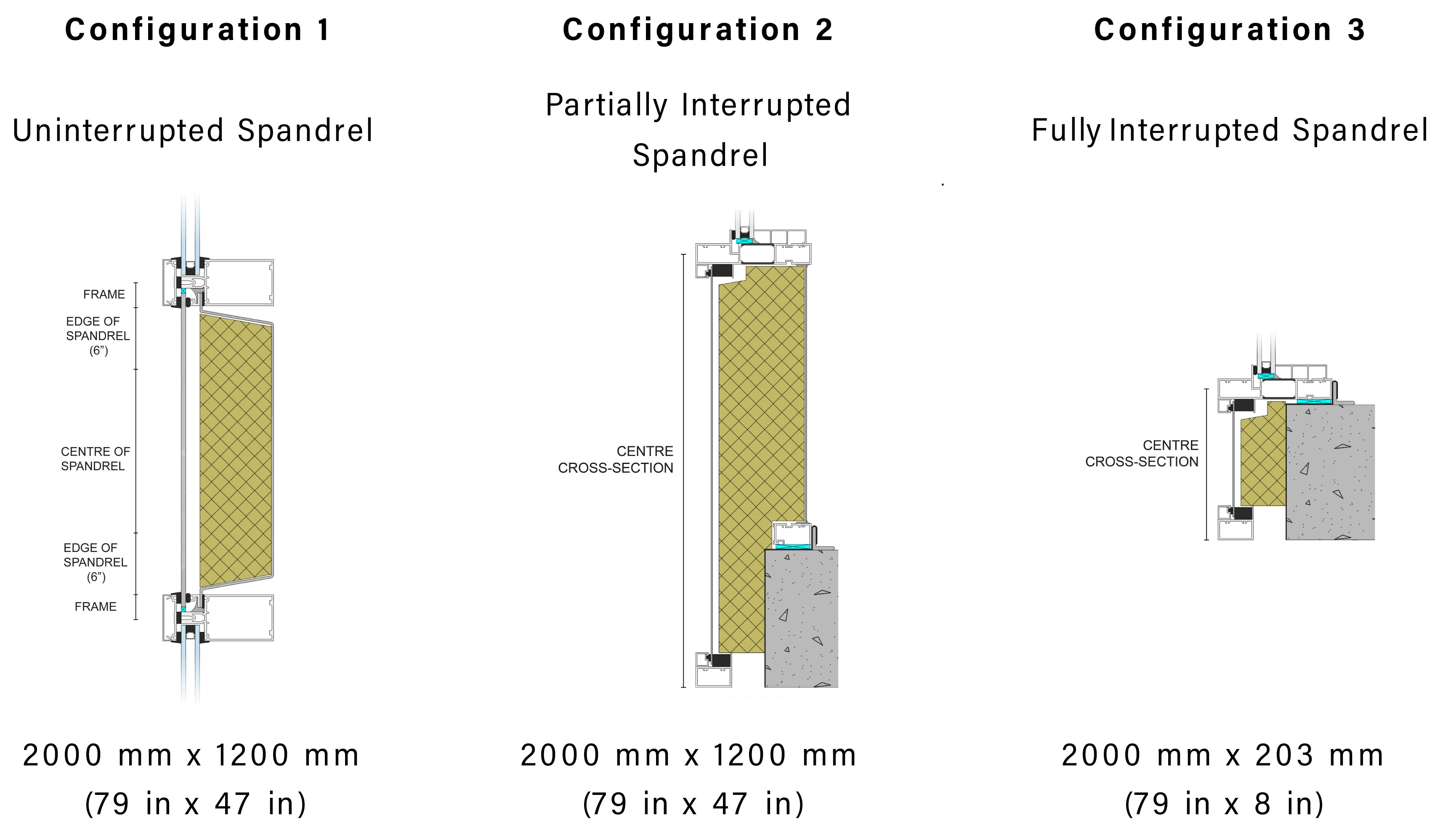

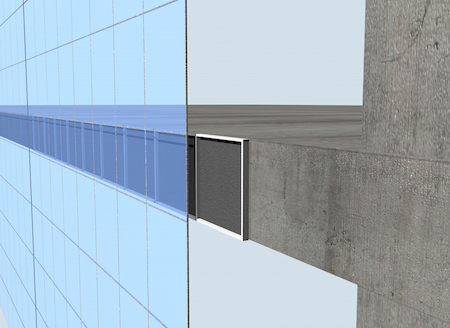

As shown in Number 1, insulation is typically made use of together with spandrel glass. When the insulation is to be used straight to the opacified surface of the spandrel glass, it is very important to work with a glass this link spandrel maker, along with the glue and also insulation providers, to make certain these items are compatible with the opacifying product. curtain wall spandrel panel detail.